Encounter with Odorito

Everyone who loves natural whetstones has heard of “Odorito,” a famous whetstone. This time, I had the good fortune to obtain a rare Odorito, and I would like to use it to review how it feels to sharpen Shironi Steel Mizuhon-yaki Mukimono kitchen knives.

What is Odorito Grindstone? ─ ─ Origin of the name and miners

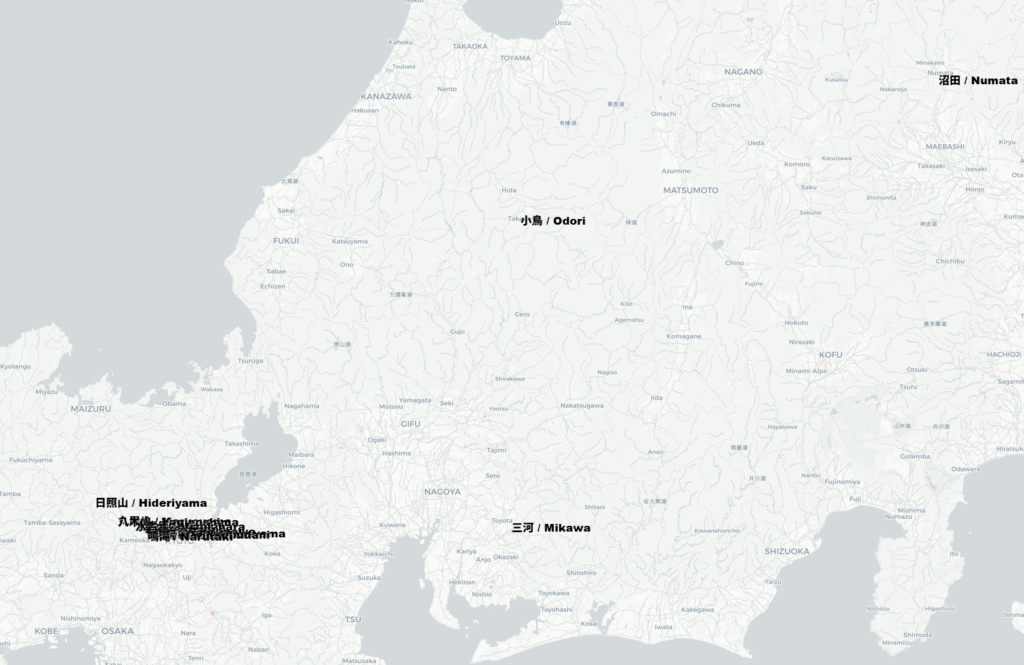

“Odori” is a natural whetstone mined in the Takayama City area of Gifu Prefecture and distributed by Mr. Yamamoto, the owner of Yamamoto Toishiten. It was discovered in a tunnel where porcelain materials were mined in the past, and was highly regarded by some as a medium grindstone for barber’s razors.

Looking at the photo, it looks very similar to the striped Nagura of Mikawa, but although it may be connected from Mikawa to Gifu Takayama as a stratigraphic zone, its production area and properties seem to be slightly different from Mikawa’s.

The word “Odori” is written “kotori” and reads “odori.

There are various theories as to the origin of the name, but we are not sure at this time. If I find out more details, I will add them. I believe it may be derived from a local dialect or a regional place name.

The miner, Mr. Yamamoto, was unable to return to the site after the cave-in accident. He seems to have passed away, and today, Odorito is almost completely absent from the market, making it a stone worthy of being called a “phantom stone. I really feel that the mining of whetstones is always accompanied by accidents. I hear that Tajima, famous for Tajima whetstone, was also closed due to a cave-in accident.

Once again, I can’t help but think that we are being allowed to use useful tools because of the life-threatening work of the miners.

Features and Comparison with Mikawa Grinding Wheel

The following is only a comparison with my own Odori, Mikawa, and Numata whetstones. Please keep in mind that even the same whetstone has different characteristics depending on the layer.

At first glance, Odori Grindstone has an appearance similar to Mikawa Shiro and Nagura Grindstone, but its performance is distinctly different. Despite being classified as a medium grind, its main feature is that its grain size is very fine and ultrafine.

While Mikawa whetstone is relatively soft and has a receptive sharpening taste while producing mud, Odori whetstone is harder and has a quicker rising edge, making it very suitable for connecting with finishing whetstone. In particular, it has an excellent ability to effectively erase the grinding marks of steel materials and the roughness of ceramic whetstones, and has the perfect balance of erasing grinding marks while not dulling the sharpness of the work.

In comparison with the Numata whetstone, the Odori whetstone has a more uniform grain size and is harder, and produces a finer finish. While the Numata wheel produces slightly sticky mud, the Odori wheel produces less mud, but this makes the edge stand up more easily and gives the impression of a clear and well-defined edge line. The Mikawa whetstone is more receptive, the Odori whetstone is more precise, and the Numata whetstone is more flexible, giving the impression that they can be separated.

Practical Review: Use for Shiro-ni wator Honyaki Mukimono Knife

The blade used in this project was a shironi steel Mizuhon-yaki Mukimono knife. Since the cutting edge is wide and the sharpening process at the finishing stage directly affects the quality, each step of the sharpening process required careful attention.

The sharpening process is as follows

1. Rough grind: Shun 220 (sintered diamond) from Kaijirushi to treat the surface of the blade.

2. Medium rough grind: Prepare the entire cutting edge with super Cera No. 600.

—This time, the rough grinding started with the rough grinding because it was also used for the main blade preparation.

3. medium grind: uniform blade preparation with the blade’s black mask No. 1000.

4. Medium-finishing grind: use Odori grind to remove scratches and connect to natural grinders.

5. Finishing grind 1: Maruoyama Ao Zuita (slightly hard) for sharpening the blade

6. Finishing grind (2): Further leveling with Nakayama Su-ita (slightly softer)

7. Edging: Okudo Habutae for both sharpness and luster

The role of Odorito is especially important in the fourth process. By using Odorito after the blade has been prepared with Kurokumaku No. 1000, it functioned perfectly as a “bridge” to improve the riding of the mud on the natural whetstone while removing fine sharpening scratches.

Sintered diamond 220 -> super Cera 600 -> blade blackout 1000 applied marks

Only the top half of the blade is where the Odori grindstone was applied. The actual blade surface shows a beautiful smooth and even satin-like reflection rather than a shiny mirror surface, creating an ideal condition for entering the natural finishing grind. The sharpening liquid is light gray.

Rarity and Historical Background of Odorito

The Odorito mining area was originally a tunnel that was opened for the purpose of digging clay minerals used as raw materials for ceramics. The grinding stone layer discovered by chance in the stratum was very thin and limited, and it is believed that the conditions were not suitable for continuous mining. In addition, since Mr. Yamamoto was digging privately, the ore was not distributed on a large scale and was mostly sold to local residents and acquaintances.

Furthermore, mining activities were terminated due to a cave-in accident, and only a small amount of the remaining inventory is currently available on the market. The quality of the stone varies widely, and very few of the stones are of good quality overall, so fine-grained pieces fetch particularly high prices.

In addition, Odorito is so naturally occurring that it is impossible to classify its grain size according to JIS standards, which in turn increases its value as a one-of-a-kind item. Because of this, Odorito is not just a whetstone, but also a collector’s item, as it is hand-ground by a craftsman with a strong belief in his craftsmanship. In terms of practical use, Mikawa, Aizu, Igarashi, and Kazama stones can be substituted for the No.1000 scratch removal and transition to natural whetstones. However, I am personally attracted to the performance and visual beauty of the Odorito whetstone.

summary

The world of natural whetstones goes beyond mere performance as tools, and is steeped in history and stories of craftsmanship. Odorito is one of them. Whenever I felt the work of Mr. Yamamoto’s hand-digging during the sharpening process, I was reminded of the joy of facing the tools.

We hope that this blog will serve as a useful record and resource for those who are interested in the little bird grindstone and natural grinding stones.