Among natural whetstones, there are some that are called “phantom whetstones” because their distribution in the market is extremely rare due to the fact that mining has already ended. One of them is the “Ozuku” whetstone, which lies in Umegahata, Kyoto. In this article, we will introduce the depth of the whetstone culture that resides in the area of Otsuki, as well as the actual record of sharpening a white 1-karat steel cutlass beef knife using three of the rarest Otsuki whetstones: “Shiro-suita”, “honsuita without nest”, and “shikidomae (gray type, ultra hard)”.

About the place name “Ozuku” and its origin

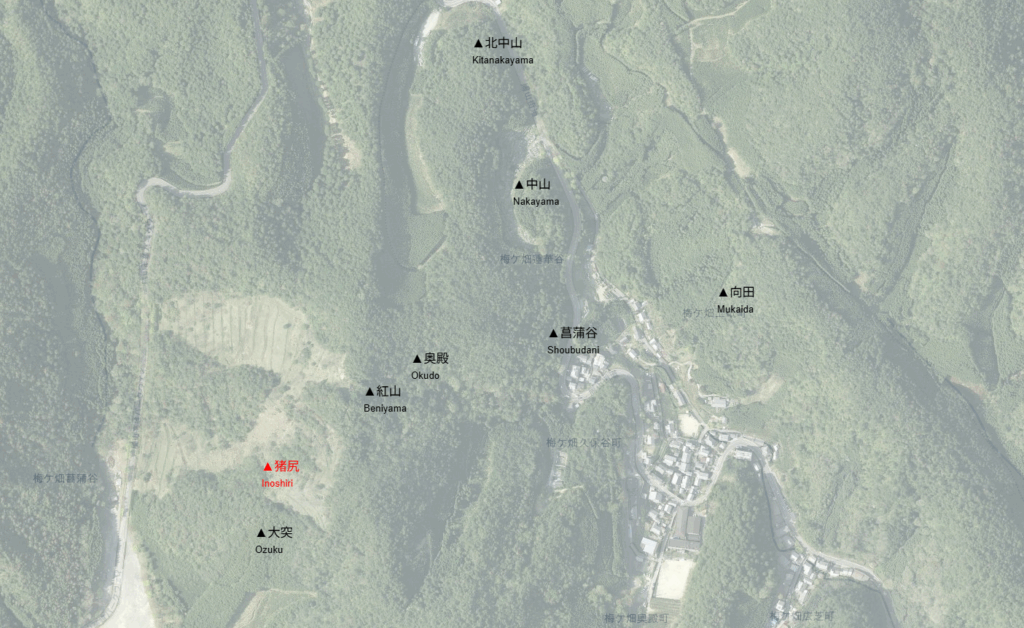

The name “Ozuku” is said to be an old place name that remains in a part of Umegahata, Ukyo-ku, Kyoto City, and is known as one of the “toishiyama” (Mt. Toishiyama). Although the origin of the word is not clear, it is thought to be derived from “tsuki”, a word used to describe a protruding shape of a mountain or the topography of a ridge.

The same character for “tsuki” can be found throughout Japan, indicating that the word has been used since ancient times to describe the topography of mountainous areas.

Although Ozuku as a whetstone production area is rarely mentioned along with Nakayama and Okudono, there are records that sharpeners and craftsmen from the Meiji and Taisho periods spoke of “Daitoshi whetstones as being extremely hard and sharp” and “having superior luster and edges rather than cloudiness.

There are very few records concerning grinding stones from Ozuku, and research is currently underway to determine if there are clear descriptions in specific documents. However, according to the testimonies of prewar sharpeners and old mining maps, there are several legends that hard-tipped whetstones were extracted from the valley on the west side of Okudo.

In addition, an old map by a natural whetstone merchant from the early Showa period (1926-1989) shows the mining site of Ozuku as “west of Okudo, Datotsukaya-no-hebi,” indicating that high-quality stones were lying within a small area.

Thus, it can be said that the name of Ozuku and its whetstone are not inferior to those of Nakayama and Okudo, but are one of the most famous whetstones with a humble but solid presence.

Characteristics of the three major brand-name whetstones: Ozuku, Nakayama, and Okudo.

Umegahata, Kyoto is home to a concentration of some of Japan’s most famous finishing stones. Three of them, “Nakayama,” “Okudo,” and “Ozuku,” are located in the same geological zone, but each produces grinding stones with different characteristics.

| producing area | Major geological formations | feature | Typical Grinding Wheels | remarks |

|---|---|---|---|---|

| mountain in the middle of a volcano, esp. in a volcanic eruption | Honkuchi-nari/ Shikidomae, etc. | Variety of variations. Variety from hard mouth to cloudy type. | Nakayama nest board, Nakayama door front, water asagi, etc. | Originates from the Kato Mine. Most varied and well-known. |

| noble’s private quarters | snubbed (of a ticket, etc.) | Highly abrasive and fast reacting. Slightly more mud | Okuden nest board, Habutae | Cloudiness comes out quickly and sharpening feeling is light |

| big headliner | Honkuchi-nari, Shikido-mae (estimated) | Fine grained and hard. Less mud. Sharp edge finish. | White nest board, nestless main nest board, and grayish thresholds | Mining has been terminated and only existing items are available. Excellent for practical use. |

All of these are “only when you use them” that they show their true value. The Ozuku, in particular, is attractive for both its reliable performance and scarcity, given the limited opportunities to obtain it.

Sharpening Review: Sharpening a Gyuto (beef knife) with white all steel with three large prongs

In this sharpening review, we used “Sakai Ichimonji Mitsuhide Kiritsuke Gyuto” and finished in the following order.

Black Mask 1000 on the blade → Rockstar 4000 → Ozuku White Nest Plate → Ozuku Nestless Hon Nest Plate → Ozuku Shikidomae (Carbide)

Usually, I review standard Hakuni steel, but this same white steel has a little more carbon content, so it is harder than Hakuni, and in return, it cuts longer. Sharpening is a bit more time-consuming due to its hardness compared to Hakuni. I have the impression that it is strong against hardness, so I will test it with Shiroichi this time.

Blade Black Mask 1000 (molding and undercoating)

For shaping the blade line and surface preparation of the cutting edge, we used the blade’s Kurokumaku No. 1000. Although Shiroichi steel has the impression of being hard and difficult to sharpen, the response at this stage was straightforward, and the grinding power was sufficient for shaping the surface. It is indeed a versatile player.

Rockstar 4000 (Surface preparation)

Next, the Rockstar 4000 was used to smooth and even out the surface sharpening scratches, creating a base for a smooth transition to the natural grinding stone. As an artificial whetstone, it is slightly harder and was effective in smoothing out the surface. Of all the Rockstar products, I especially like this 4000.

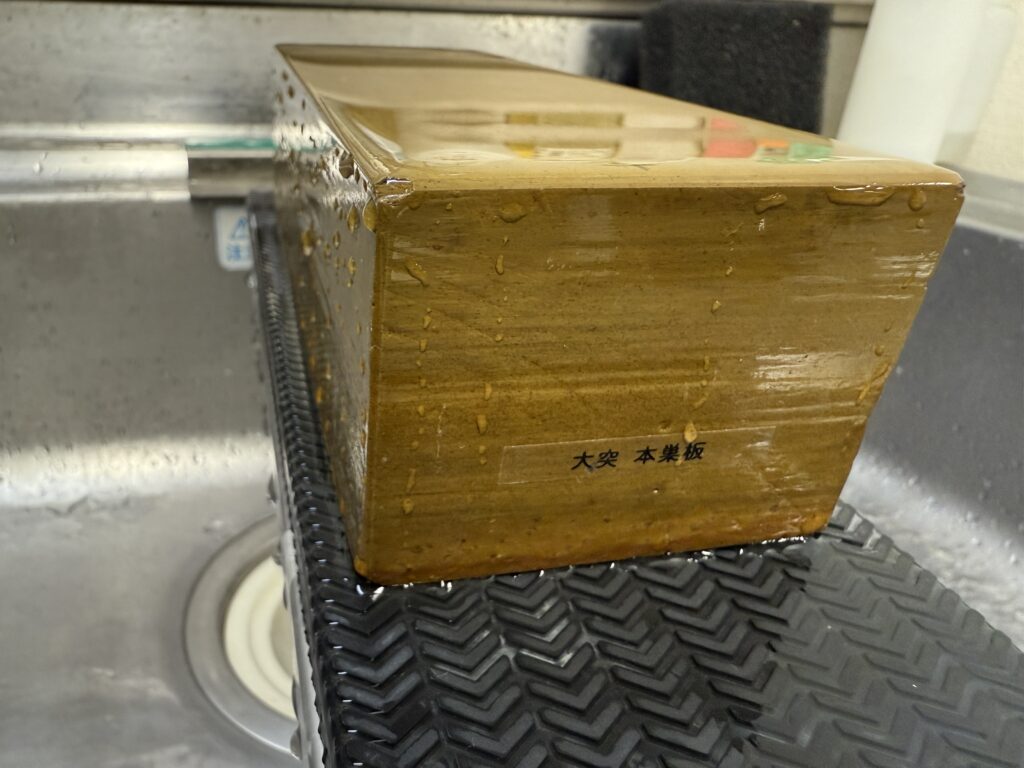

Large buttressed white nest board (frosted finish)

For finishing the cutting edge, Ozuku white su-ita (Sumi-nagashi pattern) is used. The hard grayish grindstone may be the most noticeable type of Ozuku, but the rarity is the su-ita type. It has a slightly soft and absorbent sharpening feel, and the blade and the whetstone seem to glide as if they are one. Cloudiness appears beautifully and the expression of the base metal is enhanced by the beautiful finish.

Ozuku: Nestless main nest board (shaped, glossy finish)

From this point on, it is probably a world of self-satisfaction. The white hive plate Sumi-nagashi has a tasteful cloudiness, but here we use Ozuku’s unique, shiny (but refined luster that is different from the glitter of artificial whetstone), hone hive plate without hive to further improve the smoothness of the entire cutting edge. It is an excellent whetstone for shaping the edge of a blade and finishing it with luster at the same time. According to information from a distributor with whom we have a close relationship,

(The left side is the main nest board without nests, and the right side is the white nest board with suminagashi peel.)

The sharpness of the whetstone saw does not appear to be very good, and the fine saw marks look like large undulations due to weathering. So, I think it is safe to say that it is from the late Edo period to the early Meiji period. You will not see any Ozuku Honsuita even if you visit whetstone shops all over Japan. It is a rough stone that was all taken up during the Edo period.

Ozuku, Shikido-mae (with small blade and final finish)

Finally, sharpen with a small edge with a super-hard, grayish Ozuku grindstone that looks like THE Ozuku. Since almost no mud is produced and there is a strong sense of friction, it is necessary to apply it firmly only to the edge. The finish produces a clear cutting edge and a sense of loosening without losing the edge of the white one steel.

summary

The three large Ozuku stones used in this project had different roles, but they worked together to bring the blade to perfection.

| name | role | feature |

|---|---|---|

| whiteboard | Frosting and bullion finishing | Soft, more grit, beautiful cloudiness |

| nestless main nest board | Surface preparation and glossy finish | Medium-hard to hard mouth, stable response, less uneven sharpening |

| In front of the door (Carbide) | Small blade attachment and edge adjustment | Ultra-hard mouth, virtually no mud, ideal for precision edge creation |

This kind of layered sharpening using natural whetstones not only brings out the performance of the tool, but also deeply affects the user’s sensitivity, making us feel that it is a “time for dialogue.

We will continue to explore the further utilization of Ozuku Togi stone and sharpening that makes the most of the individual characteristics of each production area.