What is a moon wheel wheel?

Tsuki-no-wa” whetstone is a relatively minor (meaning that there is very little distribution due to the small amount mined) natural whetstone production area belonging to a part of the Atago Mountains in Kyoto Prefecture, and is known by those in the know for its very unique characteristics. It is a relatively minor natural whetstone production area (meaning that it is rarely mined and has a very small distribution). See also this article for more information on the classification of geological strata. Atago-yama is the junction point of eastern and western natural whetstones, which are said to have been produced from the depths of Tsuki no Rin-ji Temple at the foot of Mt. Therefore, the name “Tsuki no Wa” seems to be derived from the name of the temple, Tsuki no Wa-dera, rather than from the name of Mt. Fudo from Tsuki no Rin no Fudo, called Akafudo because of its reddish ground color like a red pin layer.

2. features of the moon wheel grinding wheel

Appearance: Grayish ground color, sometimes with black streaks, dots, or spiral (“ring”) patterns.

Hardness: Medium-hard to slightly soft (individual differences exist)

Grain size: often classified as medium grit to medium finish

Sharpening feel: Slightly rough texture, good bite on the blade

It was originally used as a finishing touch for swords to remove sharpening scratches.

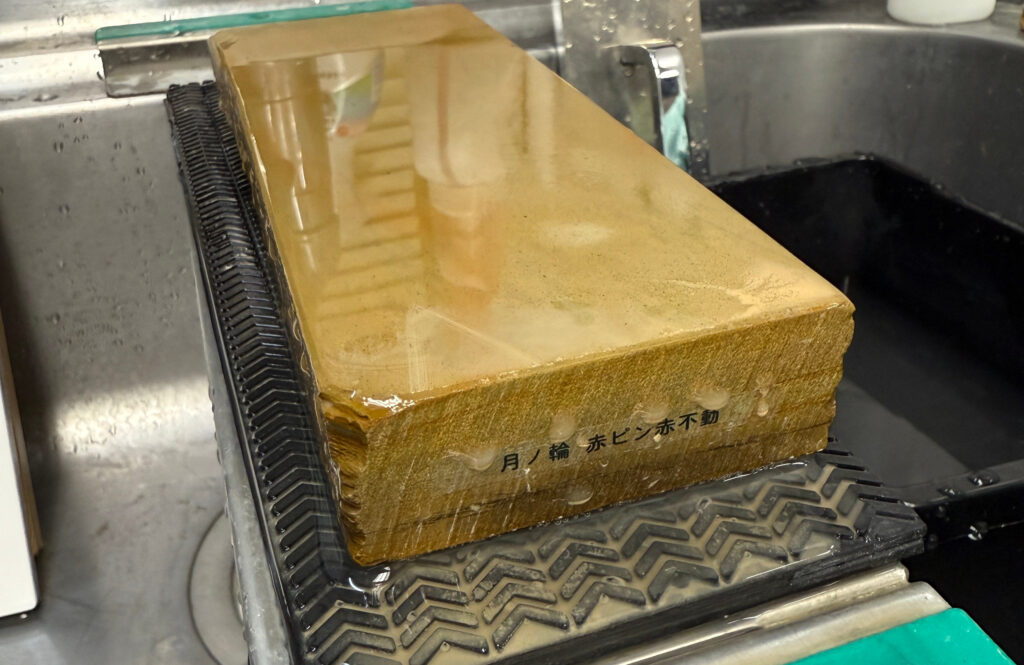

3. red immovable of the moon ring

Tsuki-no-wa is in the medium-stone formation category, so it does not have the concept of red-pin (a layer near the surface) like honseki-nari, but these three categories can only be roughly described, and the layers do not necessarily exist in each of the formation categories at each grinding stone mine. However, it is a rare stone that has characteristics similar to those of the red-pin layer of the Honseki-nari. The name “Tsuki no Wa Aka Fudo” is probably a brand name because it is a Tsuki no Wa whetstone with properties similar to the aka-pin layer.

4. wonder of sharpening feeling

The hardness of a whetstone is probably relative. For example, compared to Nakayama’s Tozen layer whetstone, the sharpening feel is softer. However, it is not so soft that it can be sharpened more and more with just the steel material of the knife, like Maruoyama’s white nest plate. In this article, I am using a Shiraji steel Funagyo knife (not as thick as a Dewa, but very easy to handle for daily use for fish) as a test. I often find that Shirani knives slip when sharpened as they are, so I use a fine grinder to sharpen them, and then slowly and gently grow the grain of the knife. I am an amateur when it comes to sharpening, so please look at the photos of my sharpening with a warm eye.

-The blade’s blackout 1000 will shape it to a certain degree.

-It is a man-made whetstone that I love, but it leaves sharpening scratches as 1000 does.

…Next, we move on to the same Shapton Rockstar 4000.

The sharpening scratches on the -1000 disappear and become a little finer.

The lower half of the boat line (near the jaw) was sharpened with Tsuki no Rin Aka Fudo.

-The lower half of the boat (near the chin) was sharpened with the Tsuki no Rin Aka Fudo.

If it is a matching knife, the soft iron will emerge, giving it a mirror-like finish. The grain is the color of a soft whetstone, but the finish is mirror-like, which is very strange.

General grinding stones

Soft grinding stone → Tendency to become cloudy

Harder grinding stones → Mirror surface tendency

It is a very strange whetstone, but one of my favorite whetstones because it is very easy to use. When you want to make a small edge, it depends on the edge you want. If you want a sharper cutting edge, you can make a small edge with an asagi type whetstone, and if you want a smooth cutting edge, you can make a small edge with this moon ring without any practical problem.

summary

Exterior Features

| (data) item | Contents |

|---|---|

| ground (color, color) | Reddish brown to pinkish light reddish. Beautifully colored and highly decorative. |

| (after a noun) indicates that that noun seems likely (e.g. rain or storm) | Individuals vary in appearance, sometimes with spots or fine threading. |

| hardness | Medium-hard to slightly hard (varies from individual to individual, but most are sticky and hard to crack). |

| granularity | Dense. The grain is fine and has a sharpening feel as if it is absorbed into the skin. |

Sharpening feeling

Sharpening feel: Moist, viscous, smooth, with no snagging.

Scratch resistance: Fine scratches are difficult to get, and the sharpened surface is very beautifully finished.

Finish: The contrast between the base metal and the blade metal is well contrasted. Smoothly prepares the ground surface of steel.

Suitable for

Finishing wheels: Suitable for final finishing of steel materials (white 1, white 2, blue 2, etc.)

Kitchen knives, planes, etc.: Suitable for tools that require both sharpness and beauty.

Compatible steel materials: Very well suited for white paper and blue paper types. Particularly recommended for use with hagane.