Table Of Contents

- Looking for the “individuality of the grinding wheel” that cannot be seen with the naked eye.

- Reasons for microscopic observation – visualization of “the effect of the grinding wheel on the blade

- How to observe – How to make a slurry slide

- Nakayama Suita – Particle structure symbolizing “lightness, homogeneity, and delicacy

- Okudo Hon-Suita – The source of the stickiness is “the size of the particles” and “milky white clay.

- Maruo White Suita – Large garnet grains and clay rich “rich grinding taste

- Conclusion: Differences among the three become the “individuality of the blade.

Looking for the “individuality of the grinding wheel” that cannot be seen with the naked eye.

Natural whetstones make a big difference in the sharpness and sharpening of knives. Nevertheless, the internal structure of the whetstone itself and the individuality of its particles are difficult to see just by sharpening in the normal way.

Many people talk about the names of the layers and production areas of whetstones, such as suita, tomae, and asagi, but not even the person sharpening may actually understand exactly where the differences come from and what particles they are composed of.

We have now collected slurry from three different types of whetstones (Nakayama suita, Okudo Hon suita, and Maruoyama Shiro suita) and observed them under a microscope to “visualize” the differences between them.

As a result, the character of the grinding wheel, which could not be seen with the naked eye, clearly appears as the uniformity of particle size, clay turbidity, and distribution, and the relationship to sharpening quality is well understood.

Below is a summary of microscopic images and sharpening impressions of each whetstone, and finally, how you can gain a better understanding of natural whetstones.

Reasons for microscopic observation – visualization of “the effect of the grinding wheel on the blade

Natural grinding stones are natural abrasives formed through a complex process of volcanic ash deposition, clay formation, consolidation due to crustal movement, and thermal metamorphism. The interior of the abrasive is a mixture of various components, including fine abrasive particles called “garnets,” clay, and silica matrix.

In the field of sharpening, these components are collectively described in sensory terms such as “grind well,” “good hit,” and “moist,” but in reality

The actual conditions are: – Garnet grain size

– Amount of clay

– Uniformity of grain distribution

We believe that “scientific differences” such as the following have a great influence on the sharpening taste.

Therefore, when you look at the slurry under a microscope,

“Where are the differences in origin?”

and “how the differences in the layers appear in the sharpening.

I thought that by observing the slurry under a microscope, it would be possible to visually understand “where the differences in origin lie” and “how the differences in layers manifest themselves in sharpening. It would be an interesting theme if natural whetstones are considered from a mere “tool” to “an object to be interpreted as a geological material.

How to observe – How to make a slurry slide

Observations were made according to the following procedure

- Lightly moisten the grind surface, and lightly mud the surface with Atoma 400

- Collect a very small amount of mud (slurry)

- Place in the center of a glass slide,

Add “less than half a drop” of water with a dropper - Place an 18 x 18 mm cover glass and press lightly to “thin-film” it.

- Taken at 460-470x

The key is to control “thinning” and “amount of water” to the utmost limit. Too much water causes the particles to sink, while too much water makes the slurry too thick and uneven, making it impossible to see the particle image. We failed several times, but by finding the optimum balance, we were able to capture the “geological character” of each grinding wheel. I will share the results of the experiment below.

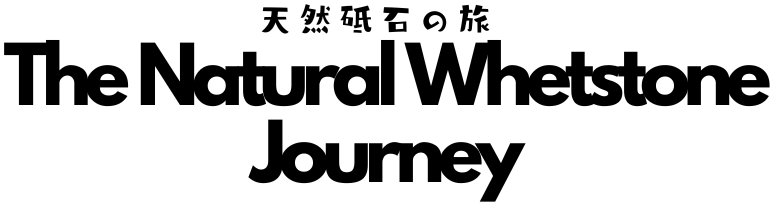

Nakayama Suita – Particle structure symbolizing “lightness, homogeneity, and delicacy

Characteristics of microscopic images

The slurry image of the Nakayama nest plate is pale cream and almost translucent.

Particles (garnets) are very fine and homogeneous

Particle size is approximately 3 to 5 µm.

Particles are uniformly dispersed and less turbid.

The entire piece appears to be “hazy,” but this may be due to the very fine particles. The black dots are garnets, but they are impressive because they are all small and uniform in shape.

Impression of sharpenability

Nakayama Zuita can be used for actual sharpening.

Nakayama suita has the following characteristics: ・Versatility (excellent balance between sharpening power and fineness of texture)

・Stands up to the blade easily

・Easily aligns sharpening scratches

The following are the characteristics of Nakayami-no-ita.

The microscopic image shows that this homogeneity leads to the stability of the sharpening performance. I believe that the result of sharpening is an “elegant” and “well-rounded blade.

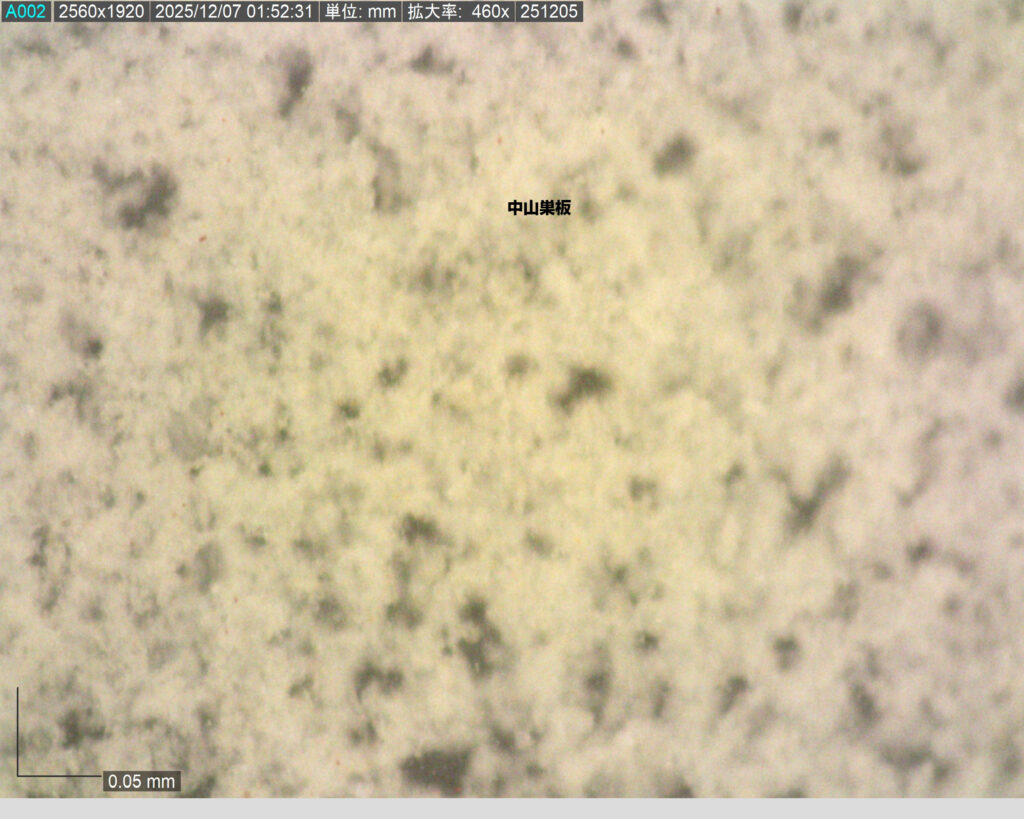

Okudo Hon-Suita – The source of the stickiness is “the size of the particles” and “milky white clay.

Characteristics of microscopic images

The slurry of the Okuden Hon suita is clearly more turbid than that of the Nakayama and has an increased whiteness.

Particle size is 6-12 µm, one size larger than Nakayama’s.

The slurry is “moist and milky” due to the high clay content.

The particles (garnets) have soft shadows and are highly cohesive.

The “roundness” and “soft shadows” of the particles are the source of Okudo’s typical suppleness. The size of the garnet particles is thought to be the source of the grinding power of Okudo’s nest plates.

Impression of sharpenability

The Okudo Hon suita Plate is

The blade is gently shaped

・Low resistance

・Sticky blade

and other characteristics.

Not as sharp and well-defined as Mt. Nakayama, not as rough as Mt. Maruo, and very well-balanced is the charm of Okudo.

The meaning of “King of Suita” can be felt from the microscope image.

Maruo White Suita – Large garnet grains and clay rich “rich grinding taste

Characteristics of microscopic images

The Maruoyama white nest board is the most “unique” of the three examined here.

Garnets are large

(Garnets are large ( 10-40 µm class fracture surfaces are mixed)

The grain size is uneven and the structure is wild, which is typical of natural abrasive stones.

Slurry is dark cream-colored due to high clay content.

Clay veil is so thick that particles “sink

Maruo at a glance.

Impression of sharpenability

The Maruoyama white suita board is used for

It is a very easy to use tool.

・It will be used for a strong and powerful tool.

・It will give a waist to the cutting edge.

It has the following characteristics

Apart from the lightness of Nakayama and the suppleness of Okudo, Maruoyama is a grinding stone suited for “thick and strong finishing”. The size of its particles makes it a strong grind (with almost no visible scratches), whether directly from the man-made 1000 or with 3000 or 4000 sandwiched in between. For practical everyday use, the Maruoyama white suita alone is sufficient for finishing. This slurry was a good introduction to natural whetstones.

Conclusion: Differences among the three become the “individuality of the blade.

What has become apparent through microscopic comparisons of the hive plates from the three production areas of Nakayama, Okudono, and Maruoyama is that the difference in geology of the whetstone is directly reflected in the sharpening quality of the stone.

- Nakayama → Fine, homogeneous, light

- Okudo → Tenacity and suppleness

- Maruoyama → large, dense, and powerful

The differences in the sharpening quality, which were all quite consistent with the structural differences that could be seen in the microscopic images, such as particle size, clay content, and turbidity strength.

When discussing the attractiveness of natural whetstones, “sensory expressions” tend to prevail. However, through this microscopic observation, we were able to visualize to some extent the “structure” that provides the basis for this description.

The individuality of the grindstone is,

- Particle size

- Amount of clay

- Formation of strata

- The number is determined by the following factors

And it is directly related to the sharpening and the character of the blade. Nakayama’s delicacy, Okudo’s suppleness, and Maruoyama’s strength.

How are they born–?

The answer to this question existed in the slurry.

Our journey of natural whetstones continues. Next, I would like to observe the differences in each layer of Nakayama (Suita/Tomae/Asagi), as well as grinding stones such as Ozuku and Ohira.

These are the records of this microscopic observation. We look forward to making new discoveries here.